How does the capacitor in the LED driver power supply decrease voltage?

Upload Time:

Sep 29, 2023

How does the capacitor in the LED driver power supply decrease voltage?

In terms of the current trend in LED driver power supply design in China, products that use the principle of capacitor voltage reduction to complete driver circuit design have gradually established a foothold in the market. LED power supply products with this design have good stability and low cost consumption. In today's article, we will briefly analyze and introduce the principle of capacitor voltage reduction in LED driver power supply.

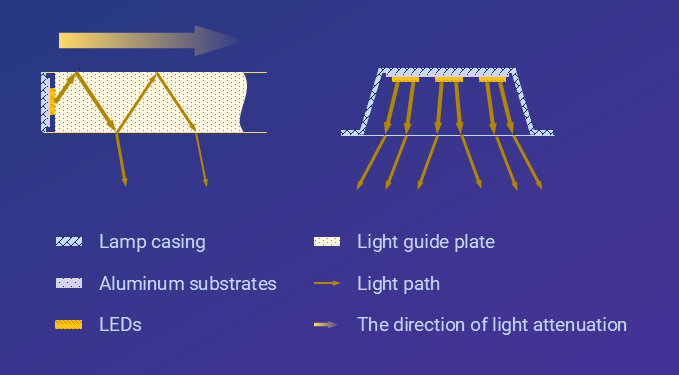

The block diagram of the voltage reduction principle in the LED driver power circuit made using the capacitor voltage reduction principle is shown in the following figure. When a sinusoidal AC power supply U (commonly known as 220VAC and 50HZ) is applied to a capacitor circuit, the charges on the two plates of the capacitor and the electric field between the plates are functions of time. That is to say, the effective value and amplitude of voltage and current on the capacitor also follow Ohm's law. When the voltage amplitude and frequency applied to the capacitor are constant, a stable sinusoidal AC current IC will flow. The smaller the capacitive reactance, the greater the capacitance value, and the greater the current flowing through the capacitor. By connecting a suitable load to the capacitor in series, a reduced voltage source can be obtained, which can be rectified, filtered, and stabilized for output. One issue that needs to be noted here is that in this circuit system, capacitors only consume energy in the circuit, so the efficiency of capacitor buck circuits is very high.

In general, LED power supplies designed using the principle of capacitor voltage reduction will consist of main driving circuits such as voltage reduction capacitors, current limiting, rectification filtering, and voltage regulation shunt circuits. Among them, the step-down capacitor is equivalent to a step-down transformer in a regular voltage stabilizing circuit, which is directly connected to the AC power circuit and can withstand almost all of the AC power supply U. Therefore, a non-polar metal film capacitor should be selected. At the moment of turning on the power supply, there may be a peak to peak value of the positive or negative half cycle of U, at which point the instantaneous current will be very high. Therefore, a current limiting resistor needs to be connected in series in the circuit to ensure the safety of the circuit, which is the essential main reason for the current limiting circuit. The design requirements for the rectification and filtering circuit are the same as those for ordinary DC regulated power supply circuits. The reason why a voltage stabilizing and shunting circuit is needed is because in the voltage reducing circuit, the effective value I of the current is stable and not affected by changes in load current. Therefore, in the voltage stabilizing circuit, there should be a shunting circuit to respond to changes in load current.

Relevant News